Hotline:400-619-2001

Chinese

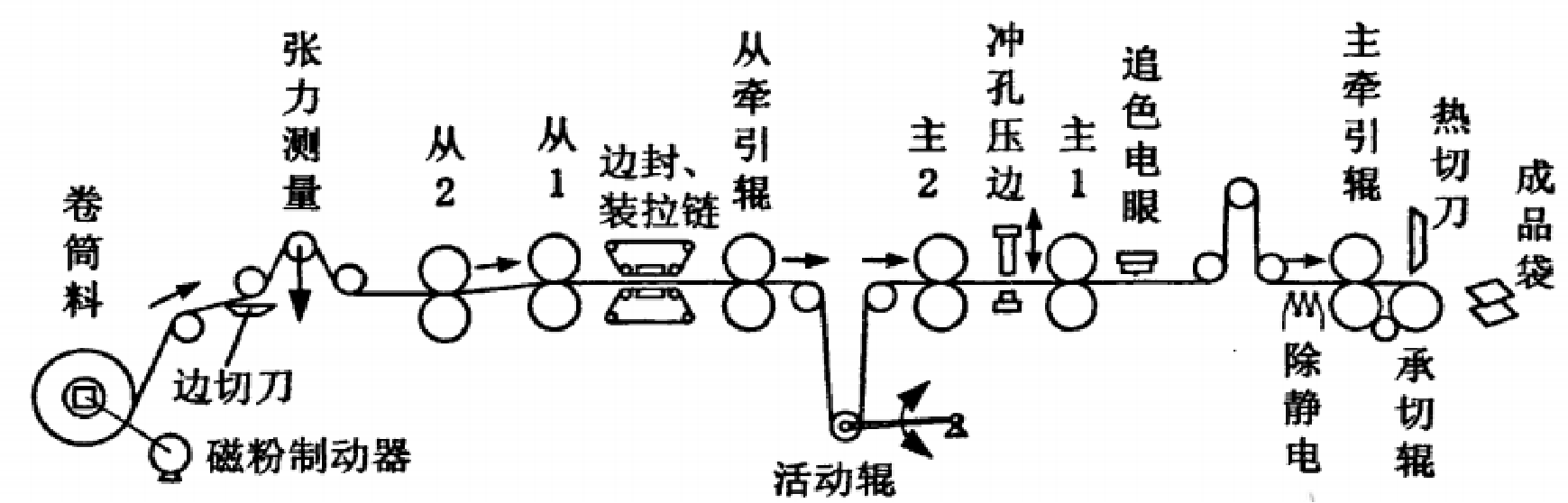

Brief introduction of bag making machine

Bag making machine is to make all kinds of plastic packaging bags or other material packaging bags of the machine, its processing range for all kinds of size thickness of different specifications of plastic or other materials of the packaging bags, generally speaking, plastic packaging bags as the main product.

Manufacturing technique

The main control process of plastic bag making machine is as follows:

1. Open the material switch to store quantitative materials by photoelectric control of material storage motor.

2. Turn on the heating control switch and warm the hot knife through the thermostat.

3. The stepper motor drives the raw material action, among which the sealing and cutting of white bag is to determine that the stepper motor stops at a fixed number of steps to realize the fixed-length control; The color bag sealing and cutting is realized by detecting the corresponding signal of the electric eye and stopping the stepper motor.

4. After the stepping motor stops, the three-phase asynchronous motor drives the hot knife to seal and cut.

5. when the sealing and cutting set the number of bags, the whole bag.

Industry application requirements

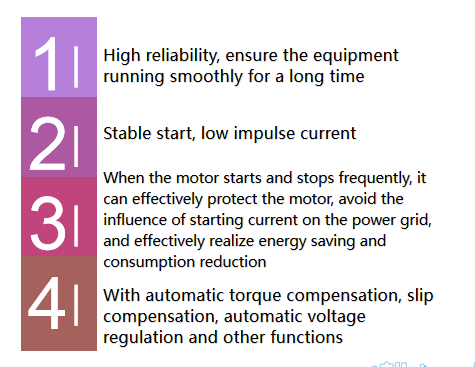

CUMARK product advantages

ES Series application cases

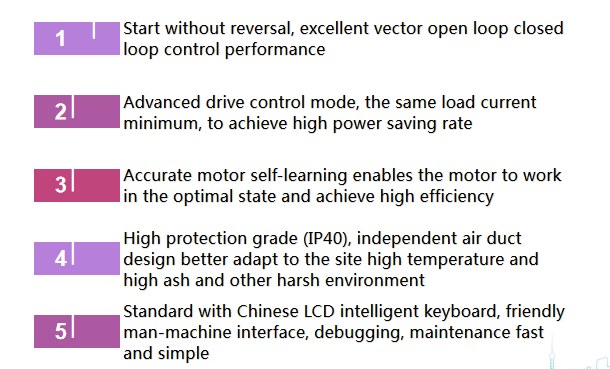

The ES580 driver + three-phase asynchronous motor is used to drive the heat sealing knife device in the process of plastic bag making machine. The heat sealing knife is mainly responsible for sealing and cutting.

The ES580 driver ADAPTS perfectly to solve the problems of responsiveness, stability accuracy and fault protection delay。

Achieved:

1. Ditto a machine control system adaptation, communication interference resistance is strong, communication fast response.

2. The low frequency starts smoothly and stably, and the current is minimized after stably running.

3. Quick frequent start and stop response, excellent open loop vector control, which can realize quick start and stop response of 0.1s ~ 0.5s.

| *Login Name: |

|

| *Login Password: |

|

| *Confirm Password: |

|

| *Image verification code: |

|

| I have read and agree "CUMARK the Service Agreement" | |

Existing account, please click here to Login

| Account: |

|

| Password: |

|

| *Image verification code: |

|

| Forget Password? |

New users, But also no accountRegister now