1. the wire drawing machine overview

The wire drawing machine that is widely used in industrial applications and is widely used in machinery manufacturing, metal processing, petrochemical, plastic, bamboo and wood products, wire and cable and other industries.

According to its use, the wire drawing machine can be divided into metal wire drawing machine (for pre-processing of metal parts such as standard parts); plastic wire drawing machine (for plastic products industry, polyester, nylon, polyethylene, polypropylene, polyester chips, etc.) Raw materials for the production of various hollow, solid garden or flat wire for deep processing of special equipment); bamboo and wood wire drawing machine (for bamboo and wood products industry in the production of chopsticks, toothpicks, barbecue sticks, etc. pull out bamboo silk, wood wire for reprocessing Special equipment) and so on.

The internal control mode and mechanical structure of the wire drawing machine can be divided into the most commonly used water tank type and straight type.

2.the water tank type wire drawing machine

The water tank type wire drawing machine is a small continuous production equipment consisting of a plurality of drawing heads. The drawing is carried out step by step, and the drawing head is placed in the water tank, and finally the steel wire is pulled to the required specifications. The wire-receiving part is dragged by a small-power motor, and the tension on the wire needs to be kept constant when the winding is kept. If the tension is fluctuated, the winding on the winding wheel will be uneven.

tank, and finally the steel wire is pulled to the required specifications. The wire-receiving part is dragged by a small-power motor, and the tension on the wire needs to be kept constant when the winding is kept. If the tension is fluctuated, the winding on the winding wheel will be uneven.

The winding section of the water tank type wire drawing machine is the core link in the control system of this equipment, and this link also directly affects the quality of the steel wire. For winding, there are usually several ways to control:

1) tension roller adjustment, the tension when winding is guaranteed by the weight of the tension roller itself.

2) Torque control is adopted, and the tension at the time of winding is determined by the magnitude given by the torque, but the tension of the wire is unbalanced due to the change of the winding diameter.

3.the water tank type wire drawing machine constitutes

The water tank type wire drawing machine is composed of a pay-off frame, a water tank drawing, and a winding roller.

Pay-off frame: There is no high control precision requirement. Generally, the wire tension provided by the wire drawing pulls the material to realize the automatic anti-wire frame.

Drawing of the water tank: The stretching part is composed of a plurality of drawing head molds, and the mold is placed in a water tank, and the steel wire is pulled to the required specifications by drawing it step by step. After the drawing of each stage, the wire diameter of the wire changes, so the working line speed of each die should also change. The entire drawing process requires an electric motor to provide drive power and requires coolant to dissipate heat during operation.

Winding roller: The wire is pulled by a small power motor. It is necessary to keep the tension on the wire constant. If the tension fluctuates, the winding on the winding roller will be uneven, and there is even the possibility of stopping the material. The winding section of the water tank type wire drawing machine is the core part of the equipment control system. Generally, the PID adjustment of the winding roller control mechanism is adopted to realize the constant line speed winding.

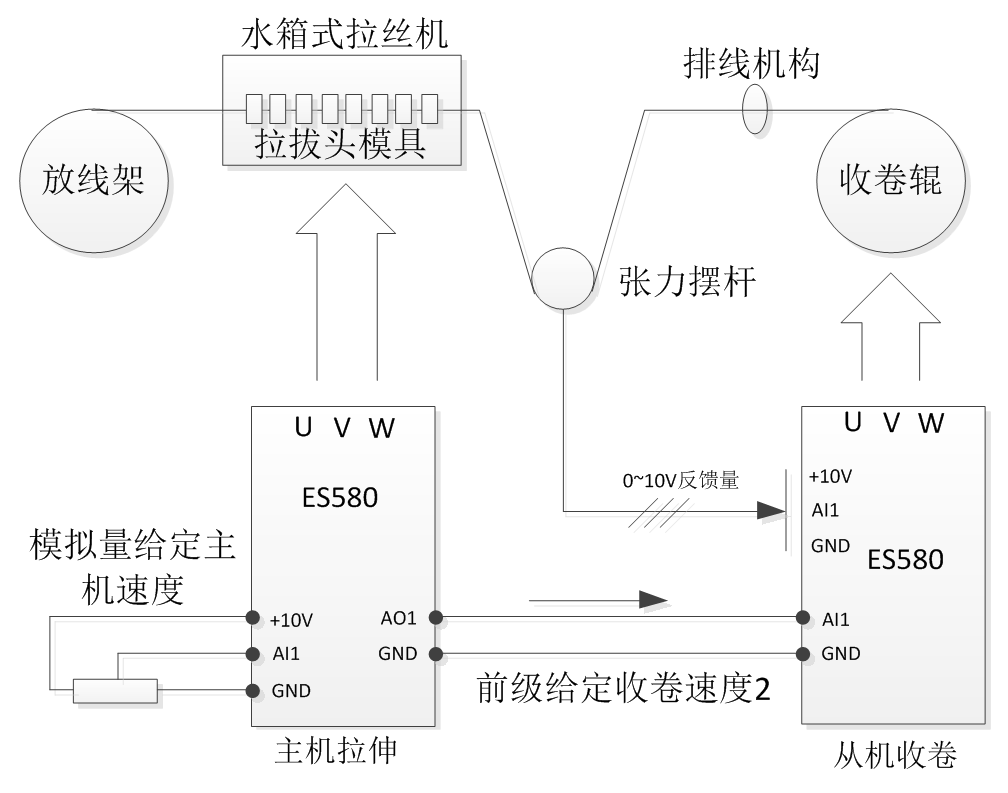

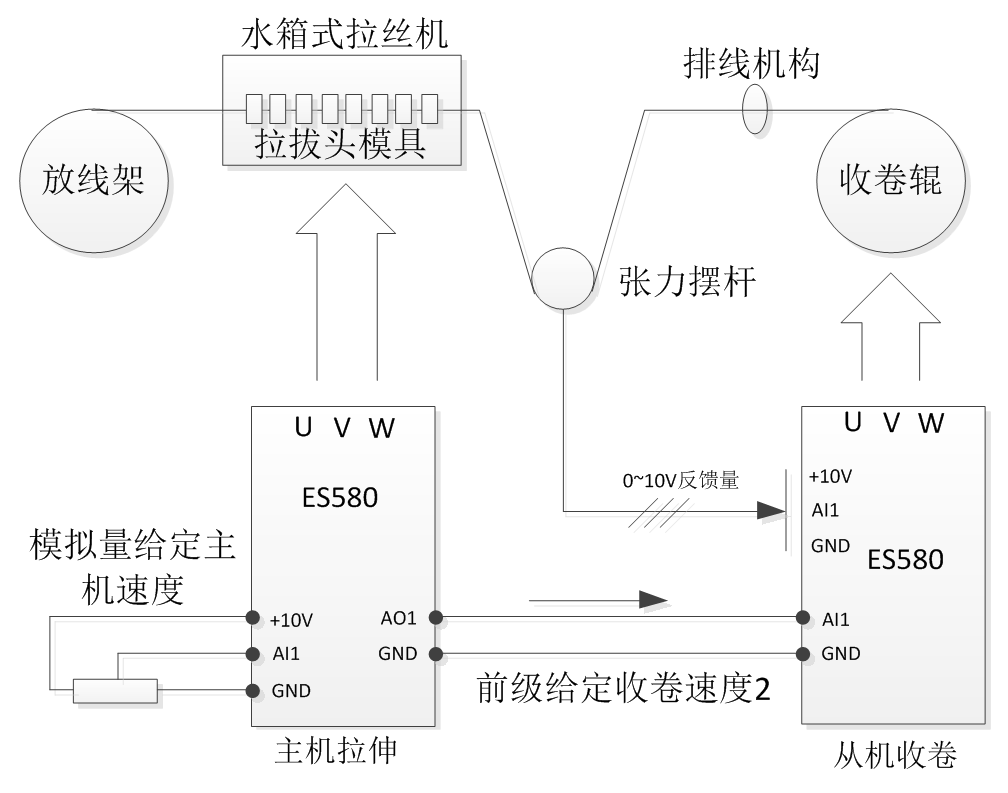

4.the working principle of the water tank type wire drawing machine

The traction stretching drive executes the line speed command and powers the entire system to pull the wire out of the tank. The line speed is transmitted to the take-up frequency converter through the port, and the swing position signal of the current synchronous winding is fed back to the winding frequency converter, and the tension control in the speed mode is realized by the automatic coil diameter calculation and the PID adjustment.

the swing position signal of the current synchronous winding is fed back to the winding frequency converter, and the tension control in the speed mode is realized by the automatic coil diameter calculation and the PID adjustment.

The winding inverter automatically adjusts the running speed of the winding motor during operation, following the change of the linear speed of the stretching inverter and the change of the winding diameter of the winding, so that the tension swing lever is always in the balance position to realize the synchronous winding control.

5.water tank type wire drawing machine technical requirements

1. The application need low frequency and large torque output. When the low frequency is moved, the mold must have enough torque and the speed response is fast.

2. When the host starts and stops, the phenomenon of disconnection must not be allowed, including the steady state of the empty disk to the full disk. If there is a disconnection fault, it should be quickly alarmed and emergency stop.

3. The equipment runs smoothly. When running at steady speed, the pendulum cannot be shaken and swings up and down.

4. When the equipment is shut down, ensure that the system line speed is synchronized.

5. high reliability, can adapt to the harsh environment of the site.

6.the water tank type wire drawing machine industry situation

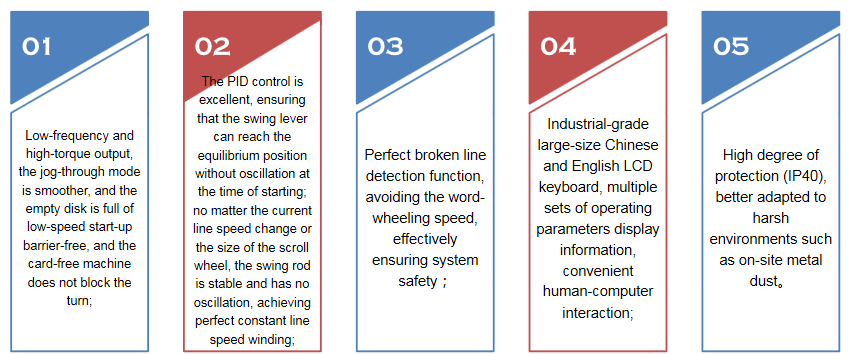

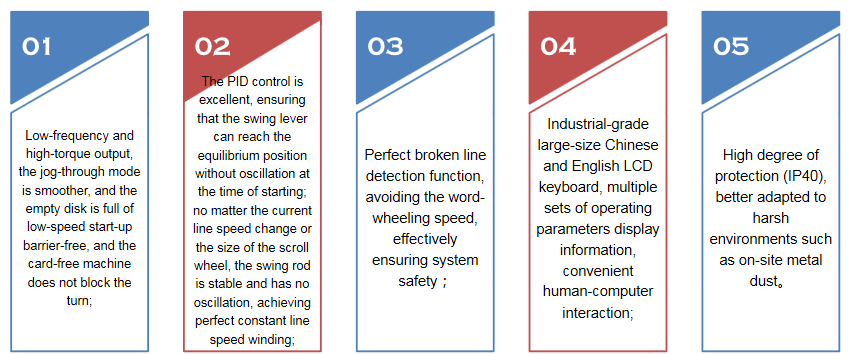

7.ES series product application advantages

8. on-site application ES series application case

The site adopts ES580 driver + three-phase asynchronous motor control, which mainly drives the stretching in the water tank type double frequency conversion wire drawing machine, and winds up two parts to achieve the synchronous constant tension control of the main machine.

The adaptation of the ES580 driver perfectly solves the problem that the low-frequency output torque is insufficient, the wire is not stable, the pendulum is shaken, and the line is often disconnected.

Achieved:

1. Smooth mold wear, stable operation and no overcurrent;

2. The low frequency starts and stops smoothly, and the current is minimized after steady speed operation;

3. Whenever the equipment is activated, the pendulum rod reaches the equilibrium position once in place;

4. The wire break detection function is powerful and effectively protects the safety of the equipment;

5. The line is stable and the product quality is improved.

9. straight into the wire drawing machine

The straight-through wire drawing machine is a commonly used equipment for processing metal wires, and can be used for wire drawing processing of high-medium and low-carbon steel wires, stainless steel wires, copper wires, aluminum alloy wires and the like. In the past, the DC motor speed was used to realize the drawing process. With the advancement of the process technology and the popularization of the frequency converter, the frequency conversion speed regulation was widely used in the straight-through wire drawing machine. With the PLC given signal, it can realize the functions of drawing material, operation and production process automation, constant line speed closed-loop control, automatic meter counting and so on.

10. straight into the wire drawing machine

The main components of the straight-through wire drawing machine include: the take-up roller, the looper, the wire drawing die and the reel, the tension swing arm, the cable arranging device and the take-up device.

According to the specifications of the wire to be produced, the corresponding wire drawing die is installed in front of each drum, the drawing die is large to small, and the last wire drawing die is the required product wire diameter specification.

The wire enters the wire drawing die and the reel 1 through the looper through the take-up device. Since the looper can be freely slipped, the reel 1 can be given a speed, and no PID adjustment is required.

There is a tension swing arm between the two reels. Starting from the reel 2, the inverter will adjust the PID speed according to the feedback signal of the swing arm to ensure the constant tension between the reels. There are many winding plans, generally adopting speed PID winding and tension winding scheme.

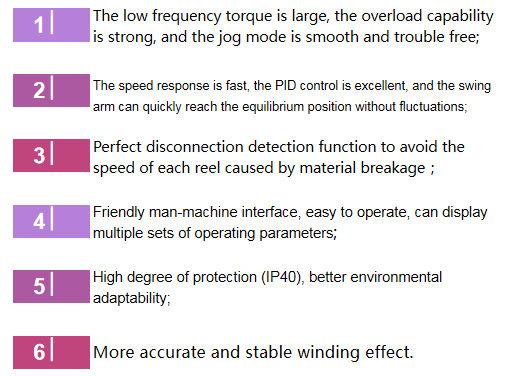

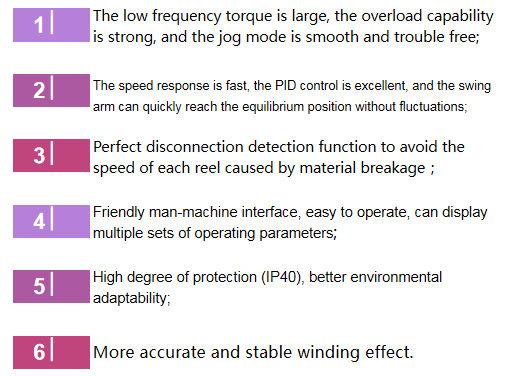

11.ES series product application advantages

12. on-site application ES series application case

The site adopts ES580 driver + three-phase asynchronous motor control, which mainly drives the main drawing reel 1 of the straight-through drawing machine, and pulls N reels to reach the main and slave synchronous constant tension and constant line speed control of the drawing machine.

The adaptation of the ES580 driver perfectly solves the problem of insufficient low-frequency output torque, slow drawing speed, unstable swing arm swing, and frequent disconnection.

Achieved:

1. The low speed jog mode is smooth and there is no overcurrent fault;

2. When starting and stopping, the swing arm can respond in time, keep the tension constant, and the speed increases and decreases steadily;

3. PID speed control winding and tension winding effect is significant;

4. The disconnection detection function effectively protects the safety of the equipment and avoids flying;

5. The equipment runs stably, the drawing efficiency is high, the speed is fast, and the quality of the product is guaranteed.

tank, and finally the steel wire is pulled to the required specifications. The wire-receiving part is dragged by a small-power motor, and the tension on the wire needs to be kept constant when the winding is kept. If the tension is fluctuated, the winding on the winding wheel will be uneven.

tank, and finally the steel wire is pulled to the required specifications. The wire-receiving part is dragged by a small-power motor, and the tension on the wire needs to be kept constant when the winding is kept. If the tension is fluctuated, the winding on the winding wheel will be uneven.

the swing position signal of the current synchronous winding is fed back to the winding frequency converter, and the tension control in the speed mode is realized by the automatic coil diameter calculation and the PID adjustment.

the swing position signal of the current synchronous winding is fed back to the winding frequency converter, and the tension control in the speed mode is realized by the automatic coil diameter calculation and the PID adjustment.