Hotline:400-619-2001

Chinese

Investor Relations

Products

Follow usCUMARK Weibo

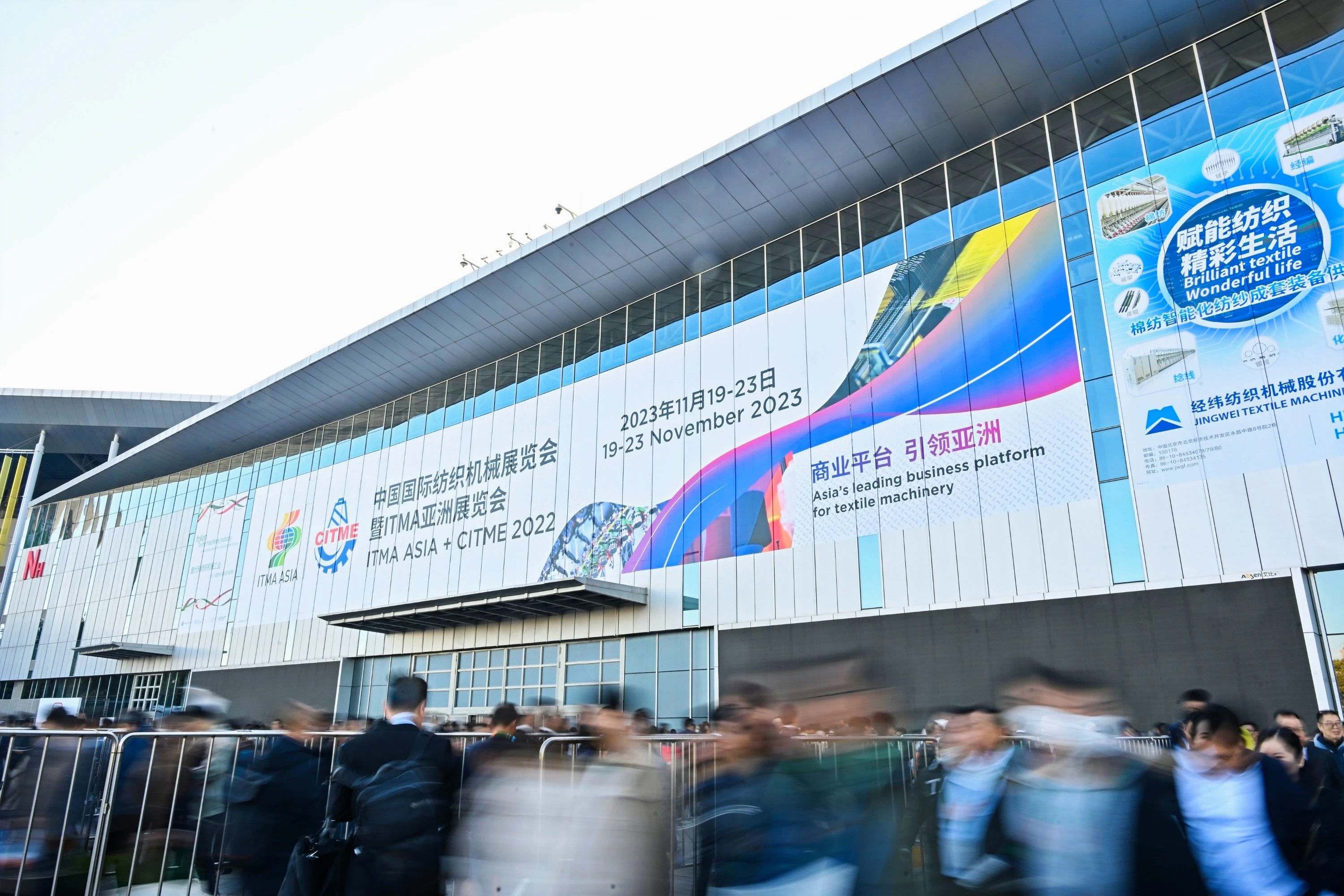

On November 19, 2023, the China International Textile Machinery Exhibition and ITMA Asia Exhibition, an important bridge for global supply and demand docking and technological communication in the textile machinery industry, were held in Shanghai. The Shenzhen Cumark team solemnly participated in the exhibition.

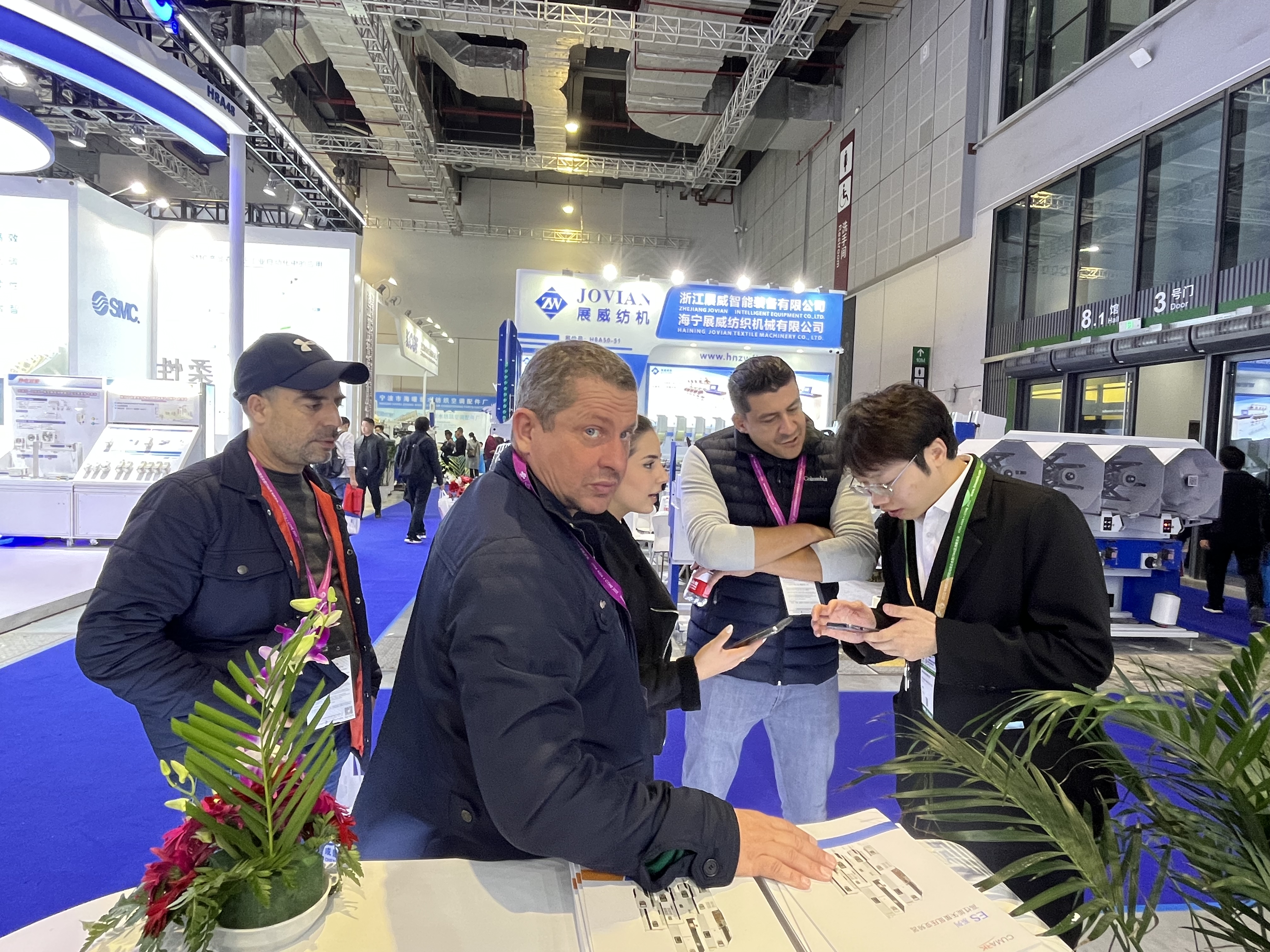

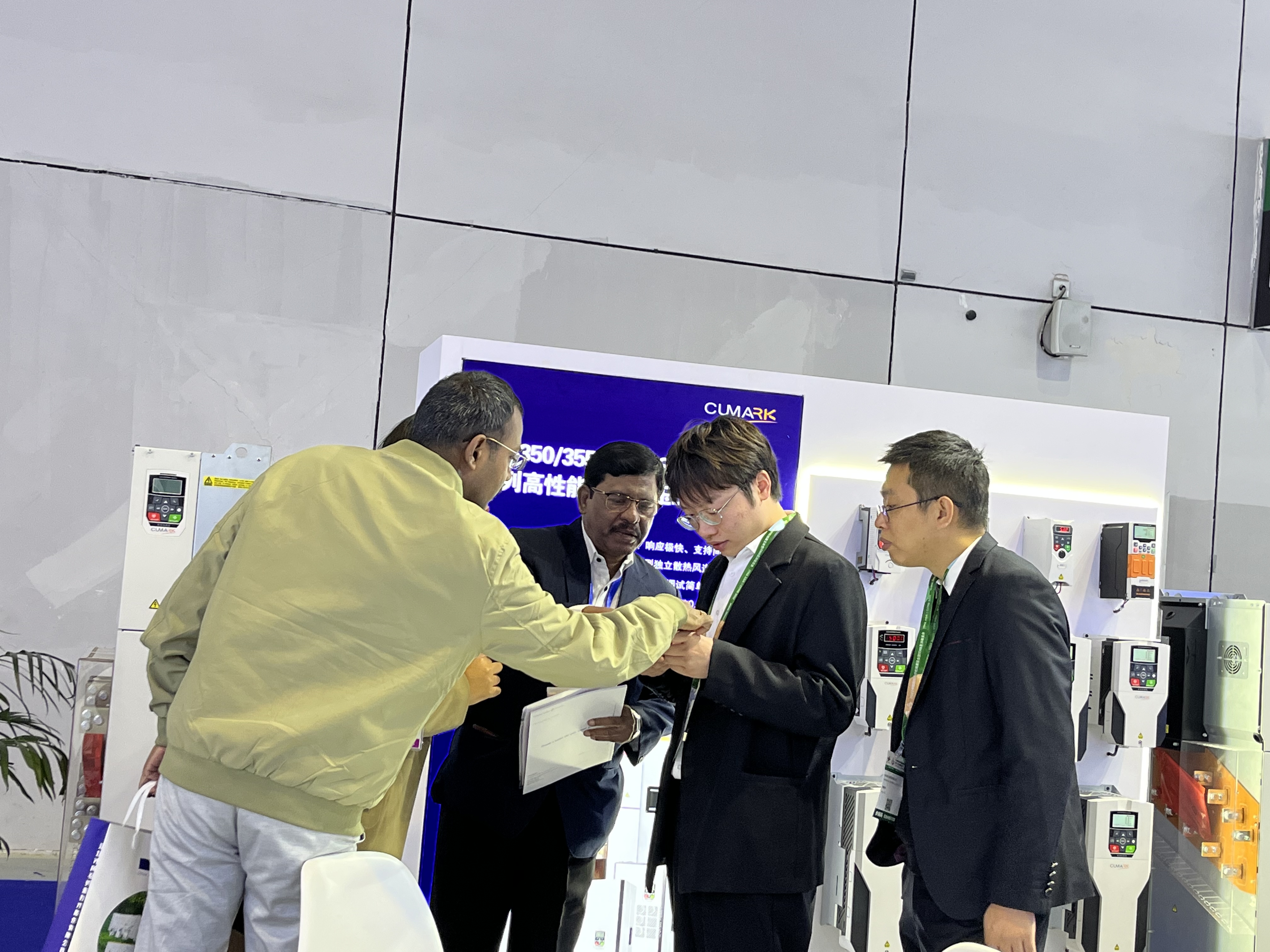

On the first day of the exhibition, the exhibition hall was filled with excitement, and well-known domestic and foreign textile machinery manufacturers gathered here. Cumark booth attracted an endless number of visitors, attracting overseas customers from more than 30 countries and regions, including Brazil, South Korea, Japan, India, Türkiye, Bangladesh, Pakistan, Croatia, Uzbekistan, etc.

"How is the product performance?" "What communication is supported?" "What is the actual working condition of the product application?" "How is the company's after-sales service?" At the exhibition, the audience's inquiries were incessant. The sales engineers of Cumark patiently answered the audience's inquiries one by one, and demonstrated Cumark's application cases in the textile industry and other industries to the audience, gaining unanimous recognition from the on-site audience.

Application case presentation:

The sustained application of the CUMARK low-voltage high-performance frequency converter ES series in textile spinning machines and double twisting machines reflects the brand effect and cohesion of CUMARK in the global and international textile machinery industry. This exhibition will also continue to provide assistance for the deepening and stabilization of international textile machinery trade cooperation, and contribute textile machinery strength to the high-quality development of the global textile industry.

1.The Application of Cumark Low Voltage High Performance Inverter ES Series in Textile Spinning Machine

Industry application requirements:

• High reliability, ensuring long-term stable operation of equipment

• Start smoothly without reversal, reduce yarn breakage rate, and improve product quality

• Can achieve certain energy-saving effects

Industry situation 1:

<Power frequency operation>

• The high starting current has a significant impact on the machinery, which can easily cause yarn breakage

• Speed regulation requires replacing the belt pulley, which is inefficient

• High operating noise, high failure rate, and high maintenance cost

Industry situation 2:

<Variable frequency+asynchronous/permanent magnet motor>

• Control asynchronous motor scheme with limited energy-saving effect

• Low frequency efficiency and severe reactive power loss

• Poor reliability, difficult to adapt to high-temperature environments

• Poor control performance of permanent magnet motors and severe demagnetization of the motor

In response to the unique characteristics of the spinning machine industry, in order to strengthen the adaptation to the special installation methods of the industry and adapt to the harsh environment on site, Cumark has launched an industry-specific machine - a special driver for textile spinning machines.

The use of ES580L driver and permanent magnet synchronous motor can well meet the needs of the industry. According to the process characteristics of the spinning machine, select a multi-stage speed control method:

• Slow operation during the yarn raising stage facilitates the connection;

• Reducing the motor output speed during the small yarn stage can effectively reduce the yarn breakage rate;

• Increase the motor output and increase production during the intermediate yarn stage that is not prone to breakage;

• Reduce the motor speed appropriately during the large yarn stage to reduce the breakage rate and improve the quality of the product.

-Energy saving renovation site of a spinning machine in Zhejiang-

Key points of special aircraft products:

• Adopting a fanless design and wall mounted installation method can better meet the spinning environment. Fans can also be installed at the factory according to the severity of the on-site environment.

• Convenient implementation of common DC bus design.

• Textile specific variable frequency, with built-in process card. During the variable frequency transformation, a new drive system was replaced for the user's spinning machine, reducing its electrical control system failure rate by 80%. There is a good energy-saving rate in energy-saving renovation projects, which has been unanimously recognized.

• Adopting a dedicated shell design, the independent large heat sink is conducive to heat dissipation, and the through wall installation can improve the protection level of cotton wool and cotton yarn. Stable operation with low failure rate reduces breakage, reduces hairiness, and improves product quality.

2.The Application of Cumark Low Voltage High Performance Inverter ES Series in Textile Double Twister

Permanent magnet synchronous motor drive:

The rotor of a permanent magnet synchronous motor is composed of permanent magnets, which have no rotor resistance loss during smooth operation, high power factor, and no need for reactive excitation current. It has gained popularity due to its ultra-high efficiency. However, its control method is complex, and improper control can lead to low energy consumption, motor reversal, motor demagnetization, and other phenomena.

Spindle system dual motor drive:

The dual motor drive mode not only improves the product quality to achieve maximum energy saving, but also brings trouble to the torque distribution. Due to the difference in mechanical structure, one motor will have a heavier load and the other will have a lighter load. The long-term operation of the motor will generate serious heat, which results in half the effort.

Industry application requirements:

• No reverse rotation of the motor during startup

• The dual frequency conversion of the spindle evenly distributes the towing torque

• The system needs to achieve start stop synchronization

• In case of sudden power outage, achieve synchronous shutdown of all systems to ensure continuous yarn production

Based on the characteristics of the double twisting machine process and the actual production situation, Cumark provides customers with the following customized solutions:

• Unique control algorithm to solve the problem of synchronous motor starting reversal;

• Spindle dual motor torque distribution function, achieving motor output balance;

• The system adopts a common DC bus scheme with built-in power-off synchronization function to ensure consistent yarn process and high product quality.

-Application site of a double twisting machine in Zhangjiagang-

Advantages of Cumark products:

(1)Starting without reverse, excellent synchronous open-loop closed-loop control performance;

(2)Built in programs such as multi-stage speed control and simple PLC settings to reduce yarn breakage rate;

(3)Advanced driving control method, achieving the minimum equivalent load current and achieving ultra-high energy-saving rate;

(4)Accurate motor matching and control enable the permanent magnet synchronous motor to work in the optimal state, reducing the risk of high-temperature demagnetization of the synchronous motor;

(5)High protection level (IP40) and independent air duct design better adapt to harsh environments such as cotton wool and high temperature on site;

(6)Standard Chinese LCD smart keyboard, user-friendly human-machine interface, quick and easy debugging and maintenance.

Empowering textile customers in all aspects:

Shenzhen Cumark was founded on March 19, 2001, and has been deeply involved in the research and development, production, and sales of power electronic transmission and automation products for 20 years. Its industry influence covers multiple countries and regions around the world, and it is a national high-tech enterprise and Guangdong Province Special Variable Frequency Engineering Technology Research and Development Center.

For a long time, Cumark has been based on the forefront of the industry, actively exploring new intelligent variable frequency drive technologies, and has always presented a high-quality development trend of high-end, green, and intelligent industries. It is committed to providing intelligent processes and textile equipment solutions for industry technological progress and upgrading, empowering and accumulating energy for the global textile industry development, and jointly creating a sustainable textile industry ecosystem.

Case sharing | Application of CUMA...

The 2023 China International Textile...

Exhibition Invitation | 2023 Shanghai...

A Wonderful Feast of Intelligent Sa...

Up in Shanghai, heading towards "green...

Warmly congratulate Shenzhen Cumark o...

Shanghai Rubber Expo RubberTech has...

Welcome to the China Coal & Mining E...

Case Sharing丨Cumark helped Shanxi X...

Cumark invites you to gather at the 21s...

Case Study丨Application of Cumark E...

Solve the Dilemma of Energy Saving丨...

| *Login Name: |

|

| *Login Password: |

|

| *Confirm Password: |

|

| *Image verification code: |

|

| I have read and agree "CUMARK the Service Agreement" | |

Existing account, please click here to Login

| Account: |

|

| Password: |

|

| *Image verification code: |

|

| Forget Password? |

New users, But also no accountRegister now