Hotline:400-619-2001

Chinese

Introduction to spinning frame

A spinning machine that draws, twists, and winds a semi-finished roving or sliver into a spun yarn during the spinning process is called a spinning frame. The spinning frame is the main machine for spinning. The output and quality of the spinning yarn are a comprehensive reflection of the advantages and disadvantages of each process of the spinning process.

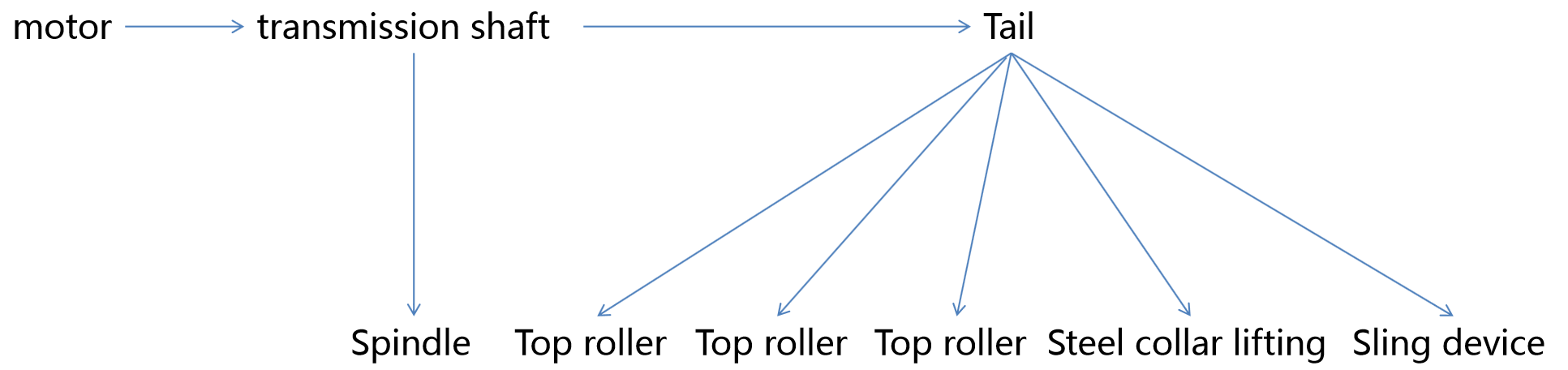

The spinning frame is basically composed of a feeding mechanism, a drafting mechanism, a twisting and winding mechanism, and the power is mainly provided by a main motor:

Spinning machine production process

The roving is unwound from the roving bobbin supported by the supporter and fed through the yarn guiding rod and the traverse guide to the drafting device for drafting. The drafted strip is output from the front roller, and is spun into a spun yarn through a yarn guide hook and a wire loop, and is wound onto a bobbin tightly placed on the spindle. When the spindle rotates, the traveler is driven by the sliver to rotate along the inner arc surface of the steel collar. Each time the wire ring rotates, it adds a roundabout to the drawn strip. At the same time, due to the frictional resistance of the traveler and the steel collar, the rotational speed of the traveler lags behind the rotational speed of the spindle, and winding occurs. The steel collar plate is moved up and down by a certain law under the control of the forming mechanism, and the strand is wound into a certain shape of the bobbin.

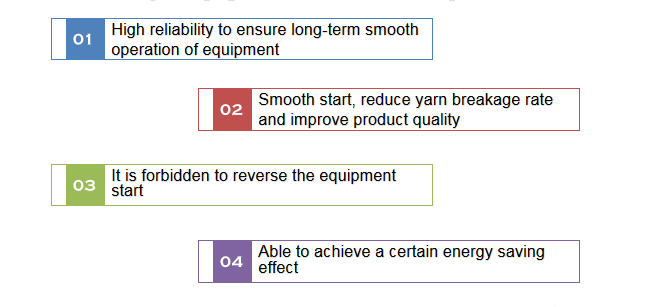

Industry application requirements

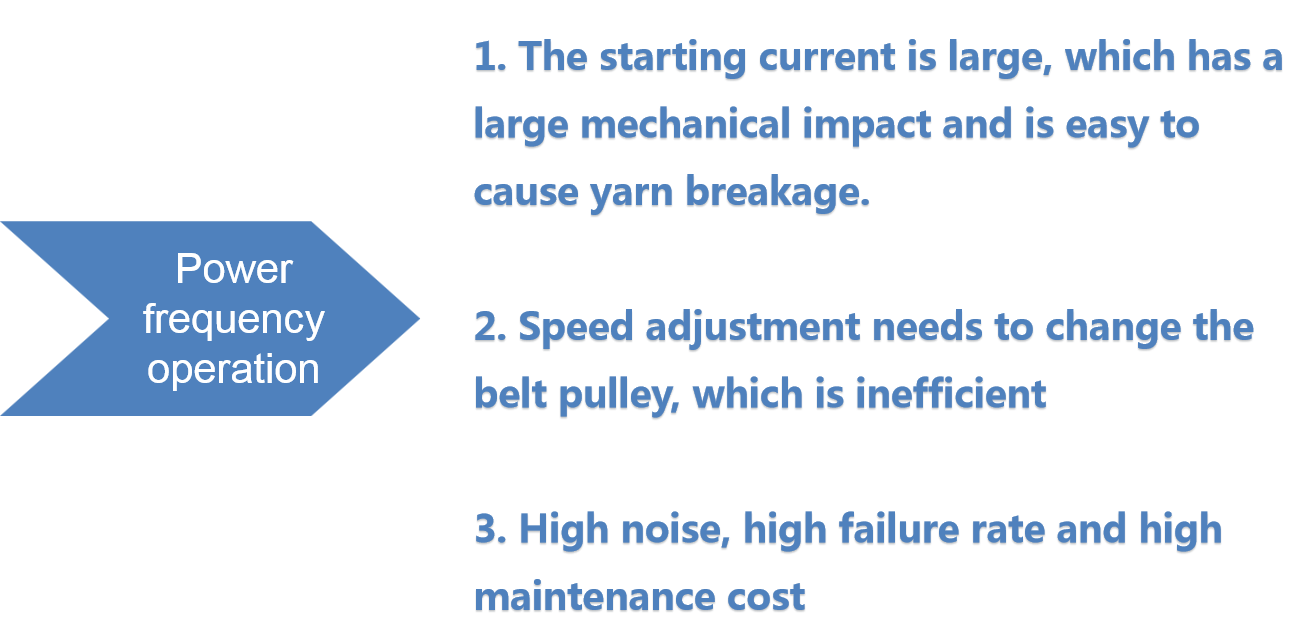

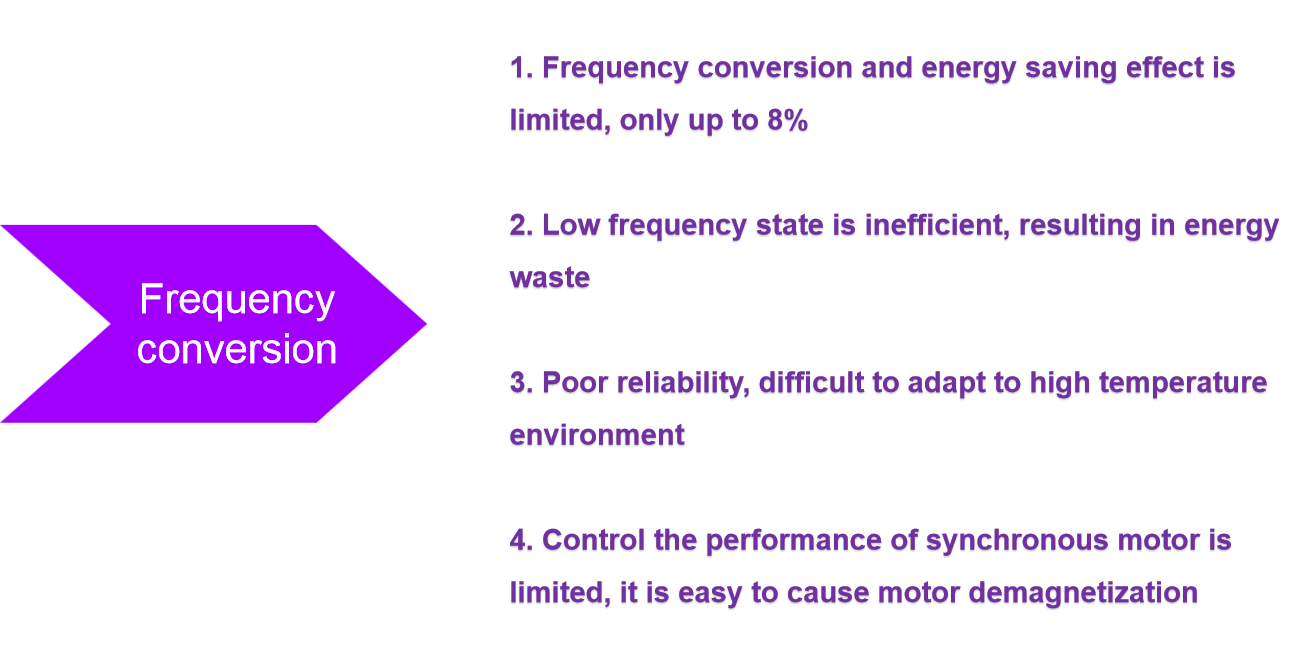

Industry status

ES series application case

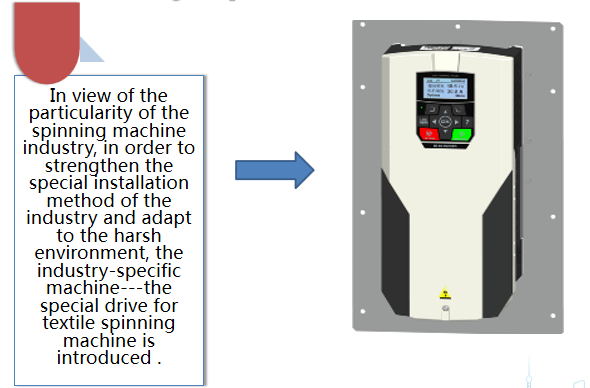

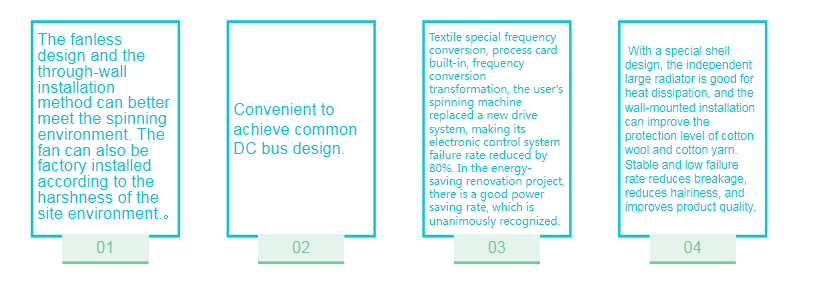

Industry-specific machine

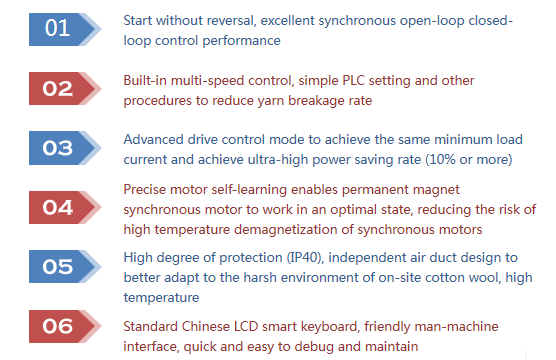

Special machine product features

| *Login Name: |

|

| *Login Password: |

|

| *Confirm Password: |

|

| *Image verification code: |

|

| I have read and agree "CUMARK the Service Agreement" | |

Existing account, please click here to Login

| Account: |

|

| Password: |

|

| *Image verification code: |

|

| Forget Password? |

New users, But also no accountRegister now